With its RFID labels (Radio Frequency Identification), Interfas is going further to ensure traceability of your goods.

These intelligent labels can convey data in a way that far surpasses the potential of printed text, bar codes or graphic images.

If you’d like to know more about the labels made by Interfas, you should visit our page « Our products » where you’ll find the RFID labels section.

However, if you are looking for solutions to secure your goods, the page on “security labels” is where you’ll find our complete offer. The standard models for VOID and tear-proof labels can be delivered under 72 hours!

How does RFID work?

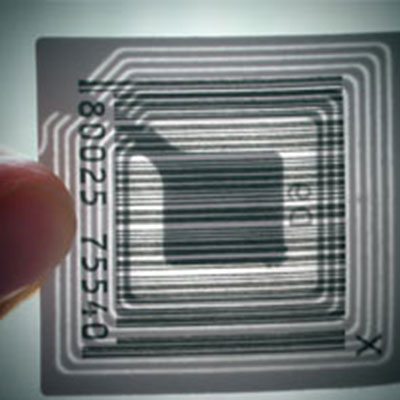

The RFID technology enables the storing of much more data than a simple barcode but mostly, it is possible to read these labels on a longer distance. The size can vary, but the way it works remains the same. The RFID label consists of an antenna, which receives and emits a signal, and of a chip, which contains the data.

You must know that it is possible, according to your needs, to choose a chip on which the data can be rewritten several times and which reading distance longer. However, these options have a cost.

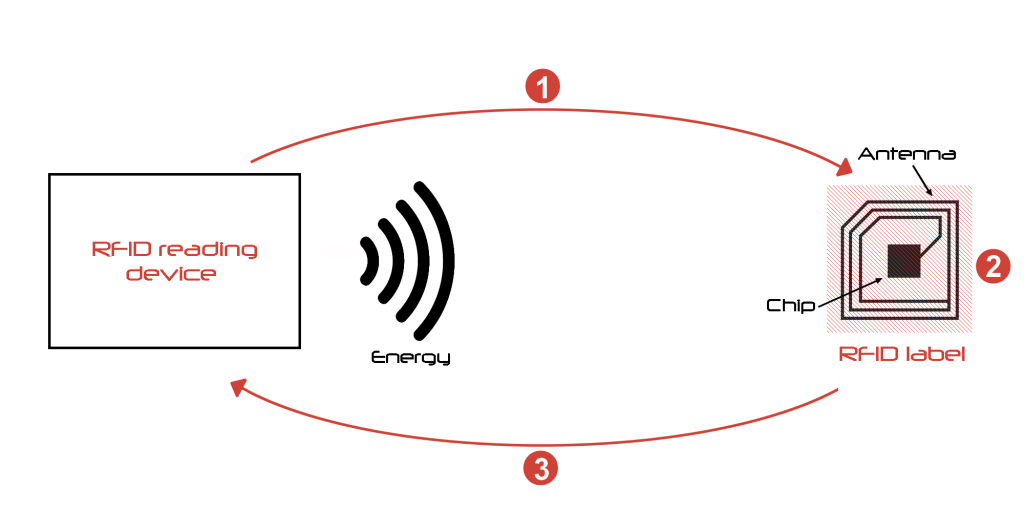

The way the label RFID works is rather simple and can be explained as follows:

First of all, you must be equipped with a stationary reading system (portico) or a portable reading device (portable reader). The portico will be used for the most powerful chips which reading distance is longer and the portable reader for the least powerful chips.

Then, this is what happens when you cross the reader near an RFID label:

① The reading device sends a signal to the chip asking for information

② The antenna receives the signal and transfers it to the active chip

③ The chip sends the information back to the antenna, which transfers it to the reading device

It is however necessary to know that RFID label have various characteristics which are going to influence on their power, their reading distance and their cost.

The power of RFID labels is partially defined by the frequencies received and emitted by the antenna. The lower the frequencies, the less powerful the chip is and vice versa. This factor strongly influences the reading distance and can be classified as follows:

- Low frequency: 125kHz

- High frequency: 13,56MHz

- Ultra high frequency: 433 et 860-960MHz

- Super high frequency: 2,45GHz

Another important difference : the one between active and passive RFID labels.

An active RFID label contains a portable source of energy (a battery) which enables a continuous activity of the chip.

A passive RFID label, on the other hand, does not contain a source of energy. It is then necessary to bring one to it when reading the data and it is the portable reader that does that.

Last major difference between RFID labels: the labels that can only be read and which data can’t be modified, the labels which data can be written once and read multiple times and the labels which can both be read and written several times.

The information contained in labels that can only be read and which data can’t be modified is engraved by the founder of the chip. It means that it is not possible by the buyer to modify the information and that he can only read them. This solution is the less expensive out of the three but the information is not customisable.

On the other hand, labels which data can be written once and read multiple times allow the user to modify and to rewrite the data engraved by the founder of the chip. However, it is only possible to rewrite the data once, but the reading remains unlimited.

Finally, labels which can both be read and written several times allow unlimited rewriting of the information contained in the chip and reading them too. Although it is the most expensive solution, it remains the most advantageous if the product has to go through several stages.

To learn more information on the RFID technology or to define which label will suit you best, you should contact our sales representatives.

Find the closest commercial agency!

What applications?

Thanks to their ability to contain much more information than a simple barcode, RFID labels are great, very performing traceability tools. They are very recommended for logistics and more generally, in the inventory management.

Besides, if your product requires going through numerous stages before being able to be used or forwarded on the market place, RFID labels that can be rewritten unlimitedly are perfectly adapted to your situation. You can modify the information at every step of the manufacturing process: no need to use several labels anymore: an RFID reader is enough. Although this label is more expensive, it is a sustainable investment which will be amortised soon!

Obviously, RFID labels are rather fragile. To prevent any loss of the information contained inside, it is possible to print a barcode, a datamatrix or a serial number on the label as well.

Some concrete examples:

Stock management is facilitated. A pallet can contain dozens, even hundreds of products. With a simple barcode, you must scan them one by one. But if they are equipped with an RFID chip and that you take the pallet towards a portico, which can read up to a 100 tags/s, you’ll save a lot of time!

In the same way, the automatic inventory can be quickly realized if products are equipped with active RFID tags. You only need to walk through the storage zone with a reading device and the information will be directly displayed on your device’s screen. Besides, the life cycle of RFID tags is rather long (several years).

Geo-tracking your products can also turn out useful when they are stored over several hectares. If an RFID chip is on the product, and that it is equipped with a battery and that the frequency is very high, you can find them more easily and very quickly. Your RFID reading device will be used as a radar.